Laser Paper Workshop

2D design for 3D forms with Cuttle parametric CAD for lasers

Workshop first done at Nordic Fablab Bootcamp 2024.

cuttle.xyz

A web-based design tool for digital cutting machines. Generate custom SVGs in seconds with templates, or use the editor to make your own designs.

Why parametric?

Cuttle origin

- Cuttle: a new CAD tool for rapid prototyping (tinyletter link is offline)

- 👆 designing a design app to design a thing https://sunseeds.xyz

Designs and tools to explore

Hands-on introduction

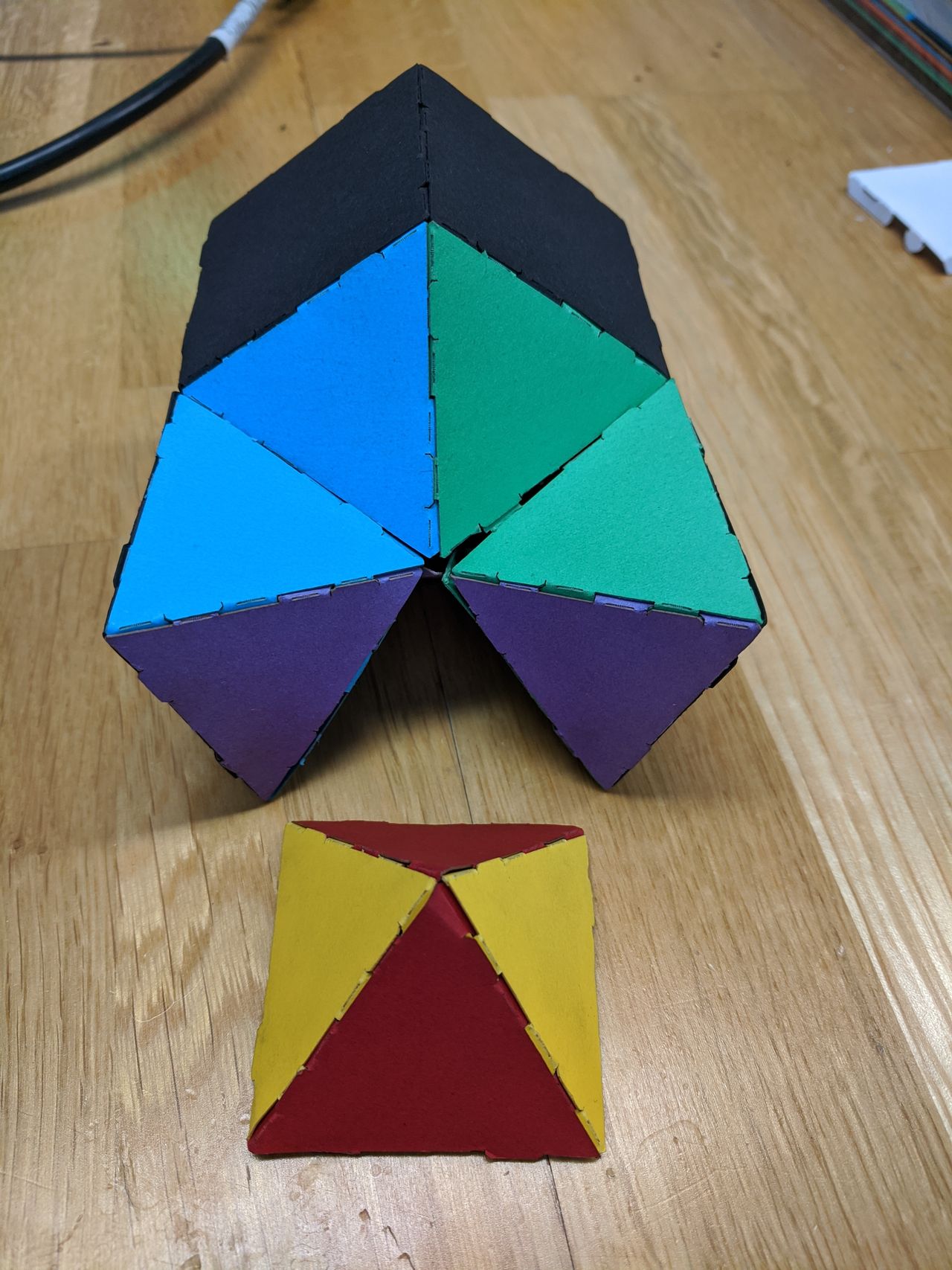

Design software and CNC tools have a big learning curve. We’ll explore some designs that can be fabricated before a workshop, to invite immediate hands-on exploration.

Can it scale up to corrugated? Big d20 or other dice? Irregular crystal shapes?

- Explore polyhedra here: https://polyhedra.tessera.li

Part cut files

Source project: Cardstock 3D Polyhedron Construction Kit – Metric

Cut layout SVGs, sized for A4:

Workshop photos

After popping out the triangles and trading them around, the participants started exploring how the parts can come together.

Inventive!

Cuttle Editor intro and Q&A

Interactive Cuttle introduction.

More project ideas

Can choose your own photos & print directly from Cuttle. Cutting and folding by hand.

CNC optional

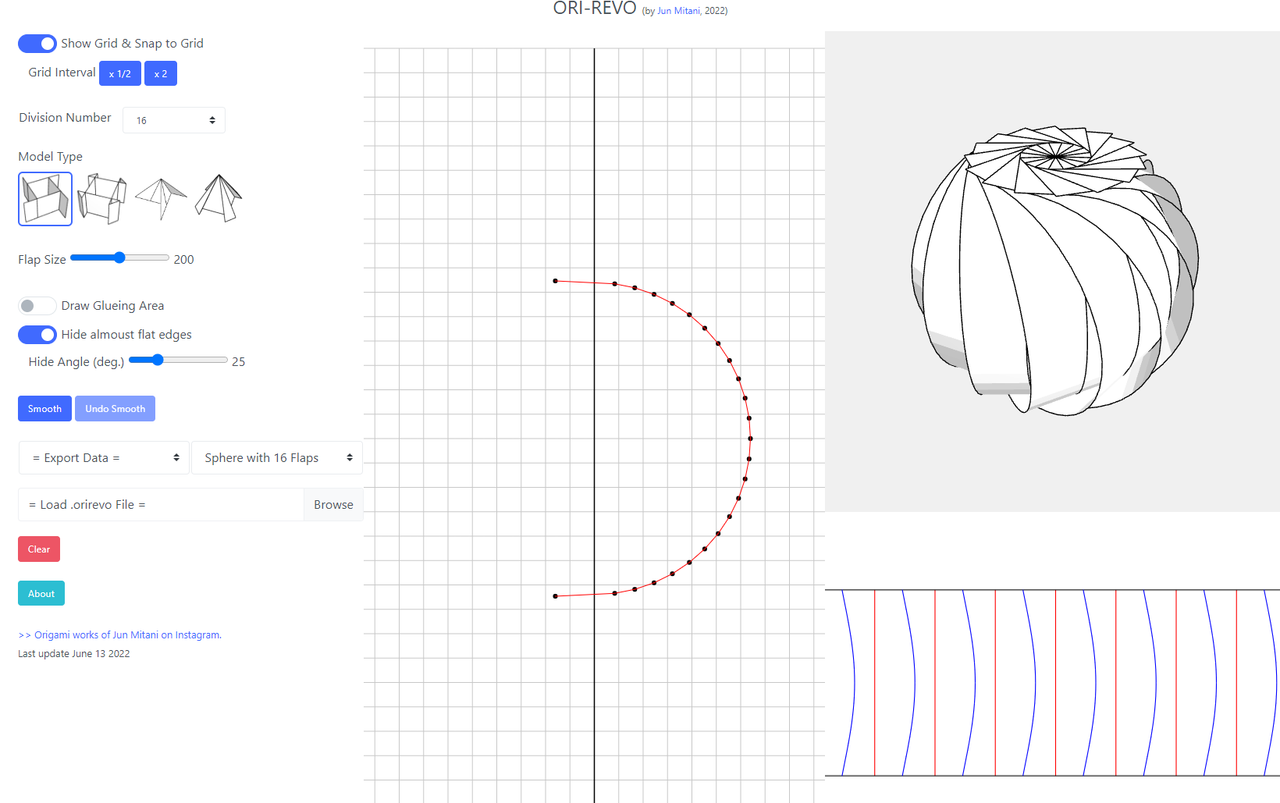

Parametric Pinwheel Paper Purse

See also “Ori Revo” below.

Villarceau Circles: slot-together torus

CNC recommended

3D Papercraft Letters Generator

Any path can generate a “strip” to give it depth.

Could the top have texture of a mountain range? (Would need a deep design dive.)

Cool Tools

Unfolder app

Papercraft tool; 3D OBJ to flat layout for cut and score.

Origami Simulator

Flat SVG to simulated folding.

“Miura Ori” … helpful to have folding lines scored beforehand.

ORI-REVO

https://mitani.cs.tsukuba.ac.jp/ori_revo/

Laser settings for paper

Don’t use probe for focus, as it will push the card stock down, and be out of focus.

Tuned on Aalto Fablab’s 80W Epilog Fusion Pro.

Speed / Power / Frequency.

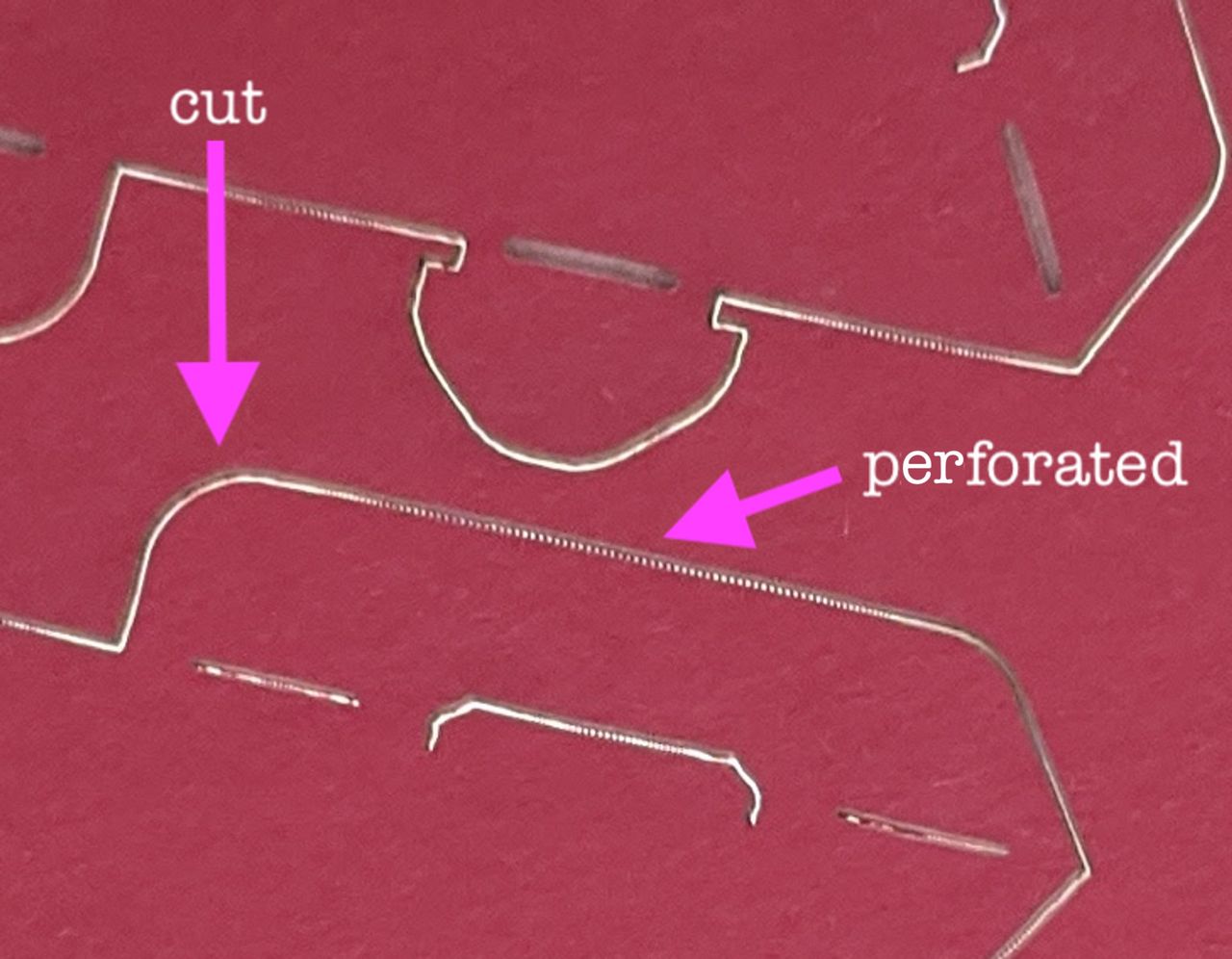

300gsm cardstock

Fully cut

85% / 35% / 15%

Smaller parts will fall out. Keep an eye on the progress to be sure that the small parts don’t block later cuts.

Perforated

85% / 35% / 10%

For holding parts in a sheet “flat-pack.” This is nice for removing keeping things organized, removing the parts from the laser in one sheet, and making kits to pack and ship.

Changing the frequency is the key to this. Acceleration interacts with this, so straighter segments will have fewer pulses per mm and therefore will have more attachment, compared to shorter segments in the same path.

Removing the parts from the sheet should be easy by folding along the path a bit.

Score, for folding lines

85% / 20% / 5%

Recommended to use “dashed lines” in design, to have half of the path unscored. Might be able to use less power.

Mark

Needs testing to see if laser can fire with low enough power to only mark card stock. Will probably function as a score line.

Normal paper

Score

100% speed, 3% power, 50% frequency

For Jonas's [[Miura Ori]] workshop.

Materials

I've been using this German "perfect ideaz" brand 300gsm cardstock.

I have also used 300gsm watercolor paper from the art supply store with the same settings and results.

More Sierpinski curve projects.

- ← Previous

2023 Studio Wall (annotated) - Next →

Week 01. Project Management